Delta-Q

Delta-Q IC Series Battery Chargers

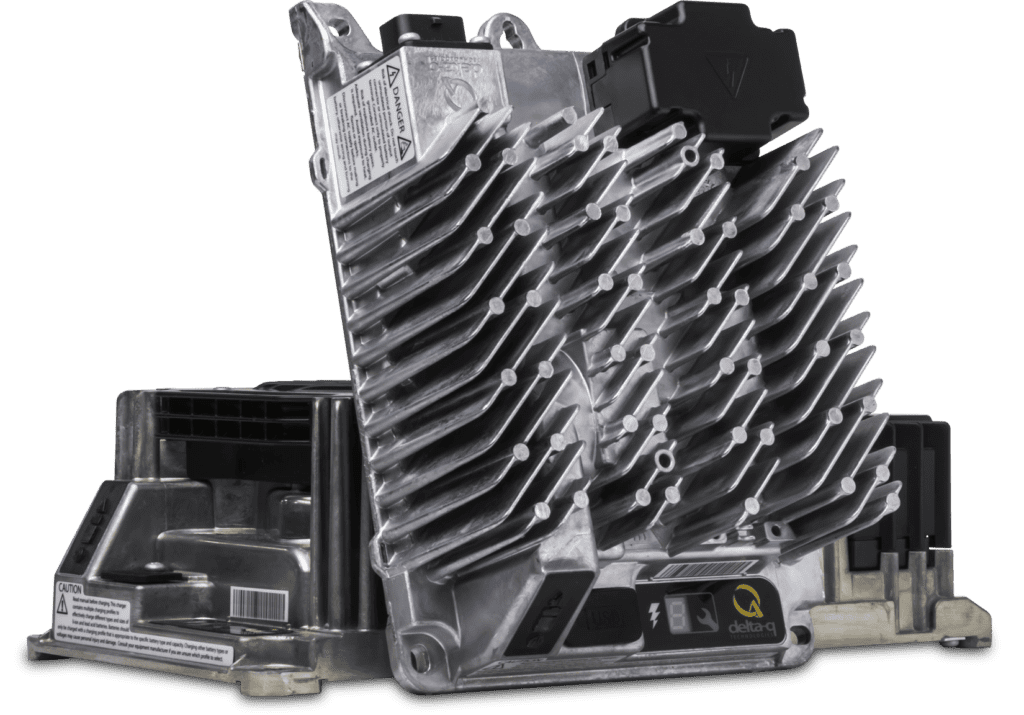

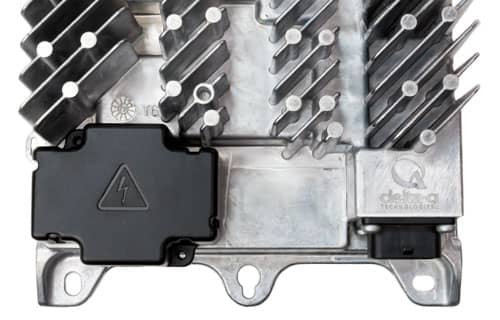

The IC Series of industrial battery chargers offer all the features and benefits in battery charging that Delta Q has come to represent, in a variety of footprints and overall charge outputs, at various voltages. The IC series features a die-cast aluminum enclosure that Delta Q pioneered, coupled with its patented USB port for charge event history, and quick changes to the charge algorithm. The IC series, when configured with the proper algorithm, can charge almost any chemistry or format of battery (lead-acid, AGM, Gel, LiFePO4, NMC, etc.) Additionally, the IC series can be configured for dozens of DC connections. After its introduction in 2014, the quality and flexibility of the IC Series chargers keep them far ahead of the pack.

BASE or COMM

Each IC Series charger comes in one of two configurations: BASE and COMM.

The COMM version includes a communication port for advanced controls, including: CANbus, Interlock relay, and remote LED signals.

Both can be configured for on-board or off-board use.

The COMM version includes a communication port for advanced controls, including: CANbus, Interlock relay, and remote LED signals.

Both can be configured for on-board or off-board use.

BASE MODEL

COMM MODEL

Key Product Attributes

Delta-Q IC Series Battery Chargers

User Interface

Clear seven-segment display indicates charging progress and completion, errors, faults, status and data.

Charge Algorithm Selection

Easily switch between charge algorithms for lead-acid (wet/flooded, sealed AGM or gel) battery chemistries and different brands with a touch of a button, providing greater flexibility for service technicians.

USB Host Port

The USB host port allows for easy factory or field configuration, algorithm/software update, and charge cycle data downloading.

Customizable and Configurable

The IC Series have a common width, enabling seamless upgrading for larger packs or faster recharge times and can be configurable to fit multiple machines for worldwide deployment with minimal SKUs.

Data Analysis

Support charge cycle data analysis across multiple chargers and battery packs for advanced fleet management with the IC Series data analysis tool.

Universally Effective

Capable of operating reliably on any single-phase grid worldwide, the IC Series is highly efficient, leading to electricity savings and shorter charge times.

Engineering for Reliability

The IC Series hardware architecture was engineered on the principle of design and manufacturing reliability. With a streamlined assembly, the charger is designed for manufacturing success, avoiding potential defects and subsequent project delays.

Charge Quality and Battery Flexibility

The IC Series provides charge quality for different lead-acid battery chemistries (wet/ flooded, sealed AGM or gel) or can support lithium charging via CAN bus communication. A button on the charger’s display enables the easy selection of another pre-loaded charge algorithm, providing flexibility for service technicians.

Seamless Integration

Optional CAN bus communication enables a link between the IC series chargers and other components for safe lithium charging and the built-in USB host port allows for downloading charge cycle data, updating charger software or charge algorithms, and to pull machine diagnostics and servicing information.

Charger Lineup for

Delta-Q IC Series Battery Chargers

IC650 Series

940-0021

IC650 Series

940-0001

IC650 Series

940-0004

IC900 Series

942-0001

IC900 Series

942-0008

IC1200 Series

941-0001

IC1200 Series

941-0008

IC650 Series

940-0002

IC650 Series

940-0005

IC900 Series

942-0002

IC900 Series

942-0009

IC1200 Series

941-0002

IC1200 Series

941-0009

IC650 Series

940-0003

IC650 Series

940-0006

IC900 Series

942-0003

IC900 Series

942-0010

IC1200 Series

941-0003

IC1200 Series

941-0010